- TOP

- Punching Tools

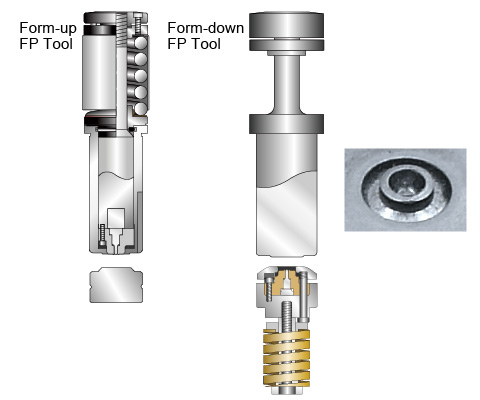

- FP Tool (Flat Positioning Tool)

FP Tool (Flat Positioning Tool)

Features & Specification

- Positioning Work Reduction

Recess remains on surface (coating surface) when using half-shear punch. Therefore, recess repairing work was necessary. But FP Tool can eliminate this post-processing because it does not leave recess.

Specification

| Form-up FP Tool | Form-down FP Tool | |

| Tool Type | Long (PDC, P&F available) ・ Short | |

| Tool Size | Bst 1 1/4” | |

| Form Side※1 | Form-up (Form is on punch side.) | Form-down (Form is on die side.) |

| Projection Dia. | φ1.9~φ4.0 (Specified Projection Sizes) | |

| Projection Height | 0.2mm~0.4mm (It varies by machine, material thickness, and material grade.) | |

| Material Thickness | 0.8mm (1.0mm common) / 1.0mm (1.2mm common) | |

| 1.6mm (specified) /2.0mm (2.3mm common)※3 | ||

| Material ※2 | Mild Steel (Not applicable for more than 441kN/mm2 tensile strength) | |

| Min. Pitch | 15mm | 17mm |

※1 Small unevenness may appear on rear side of the material marked by FP Tool. (±0.02mm or less)

※2 Not applicable for stainless steel and vinyl sheet-covered aluminum

※3 In case of 2.0mm or more thickness, some protrusion may occur around projection.