- TOP

- Bending Tools

- AFH Tooling

AFH Tooling

HG/EG/HDS/HD Recommendation

Return Bend Graph

* L:835mm M:510mm SS:200mm Ears:200mm (Right 100 Left 100) Sect.:370mm (10×2,15,20,25,40,50,100×2)

Sect. B:800mm (10,15,20,40,50,100,200,365) ___: Order Item > Heavy Gauge Punch/Die

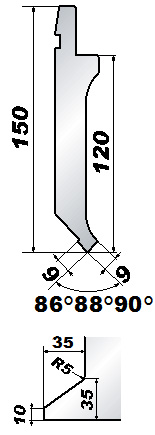

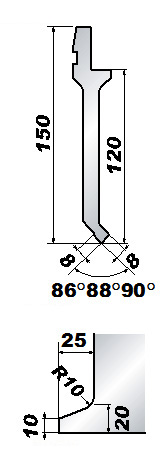

- Std.

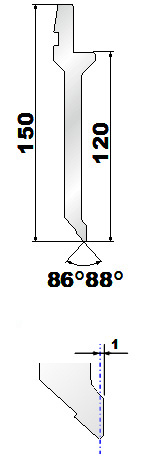

- Std. ThinType 4mm

- Burring

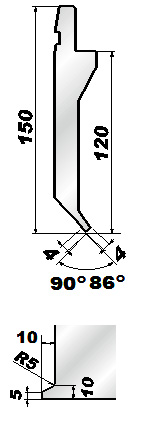

- Sash

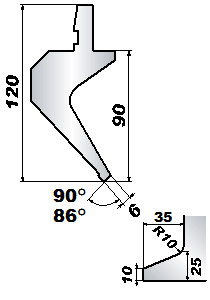

- Straight

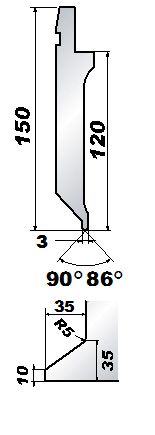

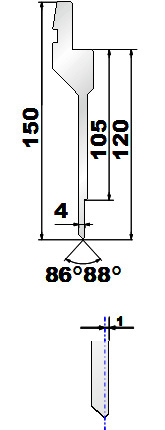

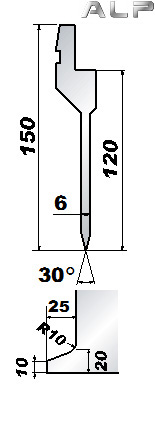

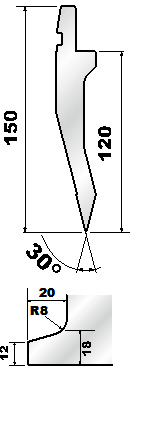

- Acute

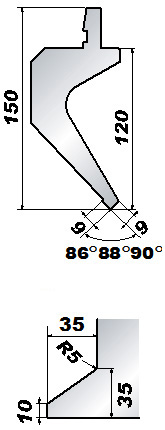

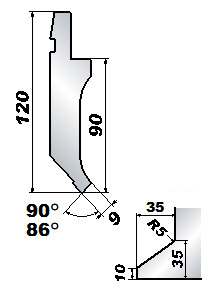

- Gooseneck

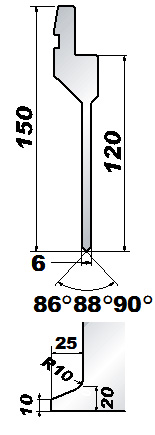

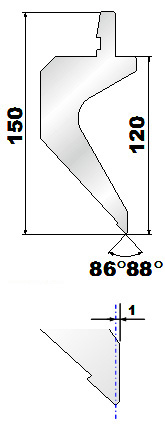

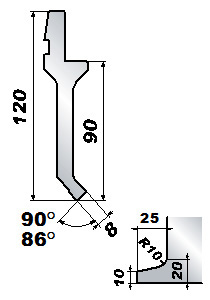

- Gooseneck Thin Type 6mm

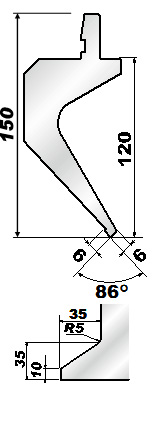

- Hemming

- H90

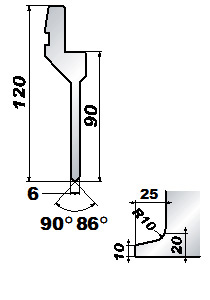

| Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight(kg) | Size | AFH120 Standard  Hardness HRC47±2 |

86° | R0.2 | A04021 | 1000kN/m | 9mm | 17.1 | L |

| A04521 | 10.4 | M | |||||

| A04722 | 4.1 | SS | |||||

| A04821 | 7.6 | Sect. | |||||

| S04621 | 16.4 | Sect. B | |||||

| A04921 | 450kN/m | 2.8 | Ears | ||||

| R0.6 | A04061 | 1000kN/m | 17.1 | L | |||

| A04561 | 10.4 | M | |||||

| A04762 | 4.1 | SS | |||||

| A04861 | 7.6 | Sect. | |||||

| S04661 | 16.4 | Sect. B | |||||

| A04961 | 450kN/m | 2.8 | Ears | ||||

| R1.5 | R04081 | 1000kN/m | 17.1 | L | |||

| R04581 | 10.4 | M | |||||

| R04782 | 4.1 | SS | |||||

| R04881 | 7.6 | Sect. | |||||

| RS4681 | 16.4 | Sect. B | |||||

| R04981 | 450kN/m | 2.8 | Ears | ||||

| R2.3 | R04091 | 1000kN/m | 17.1 | L | |||

| R04591 | 10.4 | M | |||||

| R04792 | 4.1 | SS | |||||

| R04891 | 7.6 | Sect. | |||||

| RS4691 | 16.4 | Sect. B | |||||

| R04991 | 450kN/m | 2.8 | Ears | ||||

| R3.0 | R04031 | 1000kN/m | 17.1 | L | |||

| R04531 | 10.4 | M | |||||

| R04732 | 4.1 | SS | |||||

| R04831 | 7.6 | Sect. | |||||

| RS4631 | 16.4 | Sect. B | |||||

| R04931 | 450kN/m | 2.8 | Ears | ||||

| 88° | R0.2 | B04021 | 1000kN/m | 9mm | 17.1 | L | |

| B04521 | 10.4 | M | |||||

| B04722 | 4.1 | SS | |||||

| B04821 | 7.6 | Sect. | |||||

| S0462B | 16.4 | Sect. B | |||||

| B04921 | 450kN/m | 2.8 | Ears | ||||

| R0.6 | B04061 | 1000kN/m | 17.1 | L | |||

| B04561 | 10.4 | M | |||||

| B04762 | 4.1 | SS | |||||

| B04861 | 7.6 | Sect. | |||||

| S0466B | 16.4 | Sect. B | |||||

| B04961 | 450kN/m | 2.8 | Ears | ||||

| 88° | R3.0 | R0403B | 1000kN/m | 9mm | 17.1 | L | |

| R0453B | 10.4 | M | |||||

| R0473B | 4.1 | SS | |||||

| R0483B | 7.6 | Sect. | |||||

| RS463B | 16.4 | Sect. B | |||||

| R0493B | 450kN/m | 2.8 | Ears | ||||

| 90° | R0.2 | A16021 | 1000kN/m | 9mm | 17.1 | L | |

| A16521 | 10.1 | M | |||||

| A16722 | 4.1 | SS | |||||

| A16821 | 7.6 | Sect. | |||||

| A16921 | 450kN/m | 2.8 | Ears | ||||

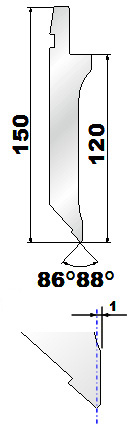

| AFH120 Standard Type-T  No Interference Hardness HRC47±2 * Burring Back Relief Spec. |

86° | R0.2 | T24021 | 800kN/m | - | 17.0 | L |

| T24521 | 10.4 | M | |||||

| T24722 | 4.1 | SS | |||||

| T24821 | 7.5 | Sect. | |||||

| TS4621 | 16.3 | Sect. B | |||||

| T24921 | 400kN/m | 2.8 | Ears | ||||

| R0.6 | T24061 | 800kN/m | 17.0 | L | |||

| T24561 | 10.4 | M | |||||

| T24762 | 4.1 | SS | |||||

| T24861 | 7.5 | Sect. | |||||

| TS4661 | 16.3 | Sect. B | |||||

| T24961 | 400kN/m | 2.8 | Ears | ||||

| 88° | R0.2 | T2402B | 800kN/m | - | 17.0 | L | |

| T2452B | 10.4 | M | |||||

| T2472B | 4.1 | SS | |||||

| T2482B | 7.5 | Sect. | |||||

| TS462B | 16.3 | Sect. B | |||||

| T2492B | 400kN/m | 2.8 | Ears | ||||

| R0.6 | T2406B | 800kN/m | 17.0 | L | |||

| T2456B | 10.4 | M | |||||

| T2476B | 4.1 | SS | |||||

| T2486B | 7.5 | Sect. | |||||

| TS466B | 16.3 | Sect. B | |||||

| T2496B | 400kN/m | 2.8 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight(kg) | Size |

| AFH120 Standard Thin Type 4mm  Hardness HRC47±2 |

86° | R0.2 | A27021 | 200kN/m | 4mm | 15.0 | L |

| A27521 | 9.2 | M | |||||

| A27722 | 3.6 | SS | |||||

| A27821 | 6.7 | Sect. | |||||

| S27621 | 14.4 | Sect. B | |||||

| A27921 | 100kN/m | 3.2 | Ears | ||||

| R0.6 | A27061 | 200kN/m | 15.0 | L | |||

| A27561 | 9.2 | M | |||||

| A27762 | 3.6 | SS | |||||

| A27861 | 6.7 | Sect. | |||||

| S27661 | 14.4 | Sect. B | |||||

| A27961 | 100kN/m | 3.2 | Ears | ||||

| 90° | R0.2 | A26021 | 200kN/m | 4mm | 15.0 | L | |

| A26521 | 9.2 | M | |||||

| A26722 | 3.6 | SS | |||||

| A26821 | 6.7 | Sect. | |||||

| A26921 | 100kN/m | 3.2 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight (kg) |

Size |

Burring |

86° | R0.2 | A05021 | 400kN/m | - | 16.6 | L |

| A05521 | 10.2 | M | |||||

| A05722 | 4.0 | SS | |||||

| A05821 | 7.4 | Sect. | |||||

| S05621 | 16.0 | Sect. B | |||||

| A05921 | 200kN/m | 2.7 | Ears | ||||

| R0.6 | A05061 | 400kN/m | 16.6 | L | |||

| A05561 | 10.2 | M | |||||

| A05762 | 4.0 | SS | |||||

| A05861 | 7.4 | Sect. | |||||

| S05661 | 16.0 | Sect. B | |||||

| A05961 | 200kN/m | 2.7 | Ears | ||||

| 90° | R0.2 | A17021 | 400kN/m | - | 16.6 | L | |

| A17521 | 10.2 | M | |||||

| A17722 | 4.0 | SS | |||||

| A17821 | 7.4 | Sect. | |||||

| A17921 | 200kN/m | 2.7 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight(kg) | Size |

| AFH120 Sash  Hardness HRC47±2 |

86° | R0.2 | A23021 | 450kN/m | 8mm | 12.3 | L |

| A23521 | 7.5 | M | |||||

| A23722 | 2.9 | SS | |||||

| A23821 | 5.5 | Sect. | |||||

| S23621 | 11.8 | Sect. B | |||||

| A23921 | 150kN/m | 2.2 | Ears | ||||

| R0.6 | A23061 | 450kN/m | 12.3 | L | |||

| A23561 | 7.5 | M | |||||

| A23762 | 2.9 | SS | |||||

| A23861 | 5.5 | Sect. | |||||

| S23661 | 11.8 | Sect. B | |||||

| A23961 | 150kN/m | 2.2 | Ears | ||||

| R3.0 | R23031 | 450kN/m | 12.3 | L | |||

| R23531 | 7.5 | M | |||||

| R23732 | 2.9 | SS | |||||

| R23831 | 5.5 | Sect. | |||||

| RS3631 | 12.3 | Sect. B | |||||

| R23931 | 150kN/m | 2.2 | Ears | ||||

| 88° | R0.2 | B23021 | 450kN/m | 8mm | 12.3 | L | |

| B23521 | 7.5 | M | |||||

| B23722 | 2.9 | SS | |||||

| B23821 | 5.5 | Sect. | |||||

| S2362B | 11.8 | Sect. B | |||||

| B23921 | 150kN/m | 2.2 | Ears | ||||

| R0.6 | B23061 | 450kN/m | 12.3 | L | |||

| B23561 | 7.5 | M | |||||

| B23762 | 2.9 | SS | |||||

| B23861 | 5.5 | Sect. | |||||

| S2366B | 11.8 | Sect. B | |||||

| B23961 | 150kN/m | 2.2 | Ears | ||||

| R3.0 | R2303B | 450kN/m | 12.3 | L | |||

| R2353B | 7.5 | M | |||||

| R2373B | 2.9 | SS | |||||

| R2383B | 5.5 | Sect. | |||||

| RS363B | 11.8 | Sect. B | |||||

| R2393B | 150kN/m | 2.2 | Ears | ||||

| 90° | R0.2 | A25021 | 450kN/m | 8mm | 12.3 | L | |

| A25521 | 7.5 | M | |||||

| A25722 | 2.9 | SS | |||||

| A25821 | 5.5 | Sect. | |||||

| A25921 | 150kN/m | 2.2 | Ears | ||||

Sash Type-T No Interference Hardness HRC47±2 * Burring Back Relief Spec. |

86° | R0.2 | T23021 | 450kN/m | - | 12.2 | L |

| T23521 | 7.4 | M | |||||

| T23722 | 2.9 | SS | |||||

| T23821 | 5.4 | Sect. | |||||

| TS3621 | 11.7 | Sect. B | |||||

| T23921 | 150kN/m | 2.2 | Ears | ||||

| R0.6 | T23061 | 450kN/m | 12.2 | L | |||

| T23561 | 7.4 | M | |||||

| T23762 | 2.9 | SS | |||||

| T23861 | 5.4 | Sect. | |||||

| TS3661 | 11.7 | Sect. B | |||||

| T23961 | 150kN/m | 2.2 | Ears | ||||

| 88° | R0.2 | T2302B | 450kN/m | - | 12.2 | L | |

| T2352B | 7.4 | M | |||||

| T2372B | 2.9 | SS | |||||

| T2382B | 5.4 | Sect. | |||||

| TS362B | 11.7 | Sect. B | |||||

| T2392B | 150kN/m | 2.2 | Ears | ||||

| R0.6 | T2306B | 450kN/m | 12.2 | L | |||

| T2356B | 7.4 | M | |||||

| T2376B | 2.9 | SS | |||||

| T2386B | 5.4 | Sect. | |||||

| TS366B | 11.7 | Sect. B | |||||

| T2396B | 150kN/m | 2.2 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight (kg) |

Size |

Straight Hardness HRC47±2 |

86° | R0.2 | A19021 | 450kN/m | - | 9.9 | L |

| A19521 | 6.0 | M | |||||

| A19722 | 2.4 | SS | |||||

| A19821 | 4.4 | Sect. | |||||

| S19621 | 9.4 | Sect. B | |||||

| A19921 | 120kN/m | 1.8 | Ears | ||||

| R0.6 | A19061 | 450kN/m | 9.9 | L | |||

| A19561 | 6.0 | M | |||||

| A19762 | 2.4 | SS | |||||

| A19861 | 4.4 | Sect. | |||||

| S19661 | 9.4 | Sect. B | |||||

| A19961 | 120kN/m | 1.8 | Ears | ||||

| R3.0 | R19031 | 450kN/m | 9.9 | L | |||

| R19531 | 6.0 | M | |||||

| R19732 | 2.4 | SS | |||||

| R19831 | 4.4 | Sect. | |||||

| RS9631 | 9.4 | Sect. B | |||||

| R19931 | 120kN/m | 1.8 | Ears | ||||

| 88° | R0.2 | B19021 | 450kN/m | - | 9.9 | L | |

| B19521 | 6.0 | M | |||||

| B19722 | 2.4 | SS | |||||

| B19821 | 4.4 | Sect. | |||||

| S1962B | 9.4 | Sect. B | |||||

| B19921 | 120kN/m | 1.8 | Ears | ||||

| R0.6 | B19061 | 450kN/m | 9.9 | L | |||

| B19561 | 6.0 | M | |||||

| B19762 | 2.4 | SS | |||||

| B19861 | 4.4 | Sect. | |||||

| S1966B | 9.4 | Sect. B | |||||

| B19961 | 120kN/m | 1.8 | Ears | ||||

| R3.0 | R1903B | 450kN/m | 9.9 | L | |||

| R1953B | 6.0 | M | |||||

| R1973B | 2.4 | SS | |||||

| R1983B | 4.4 | Sect. | |||||

| RS963B | 9.4 | Sect. B | |||||

| R1993B | 120kN/m | 1.8 | Ears | ||||

| 90° | R0.2 | A18021 | 450kN/m | - | 9.9 | L | |

| A18521 | 6.0 | M | |||||

| A18722 | 2.4 | SS | |||||

| A18821 | 4.4 | Sect. | |||||

| A18921 | 120kN/m | 1.8 | Ears | ||||

Straight Type-T * Burring Back Relief Spec. Hardness HRC47±2 |

86° | R0.2 | T12021 | 400kN/m | - | 9.7 | L |

| T12521 | 5.9 | M | |||||

| T12722 | 2.3 | SS | |||||

| T12821 | 4.3 | Sect. | |||||

| T1S621 | 9.3 | Sect. B | |||||

| T12921 | 120kN/m | 1.8 | Ears | ||||

| R0.6 | T12061 | 400kN/m | 9.7 | L | |||

| T12561 | 5.9 | M | |||||

| T12762 | 2.3 | SS | |||||

| T12861 | 4.3 | Sect. | |||||

| T1S661 | 9.3 | Sect. B | |||||

| T12961 | 120kN/m | 1.8 | Ears | ||||

| 88° | R0.2 | T1202B | 400kN/m | - | 9.7 | L | |

| T1252B | 5.9 | M | |||||

| T1272B | 2.3 | SS | |||||

| T1282B | 4.3 | Sect. | |||||

| T1S62B | 9.3 | Sect. B | |||||

| T1292B | 120kN/m | 1.8 | Ears | ||||

| R0.6 | T1206B | 400kN/m | 9.7 | L | |||

| T1256B | 5.9 | M | |||||

| T1276B | 2.3 | SS | |||||

| T1286B | 4.3 | Sect. | |||||

| T1S66B | 9.3 | Sect. B | |||||

| T1296B | 120kN/m | 1.8 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Profile |

Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight (kg) |

Size |

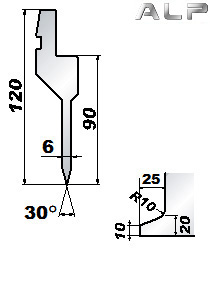

| AFH120 Acute  Hardness HRC60±2 |

30° | R0.2 | A13021 | 450kN/m | ---- | 9.7 | L |

| A13521 | 5.9 | M | |||||

| A13722 | 2.3 | SS | |||||

| A13821 | 4.3 | Sect. | |||||

| S13621 | 9.3 | Sect. B | |||||

| A13921 | 120kN/m | 1.8 | Ears | ||||

| R0.6 | A13061 | 450kN/m | 9.7 | L | |||

| A13561 | 5.9 | M | |||||

| A13762 | 2.3 | SS | |||||

| A13861 | 4.3 | Sect. | |||||

| S13661 | 9.3 | Sect. B | |||||

| A13961 | 120kN/m | 1.8 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight (kg) |

Size |

Gooseneck Hardness HRC47±2 |

86° | R0.2 | A47021 | 500kN/m | 9mm | 25.0 | L |

| A47521 | 15.3 | M | |||||

| A47722 | 6.0 | SS | |||||

| A47821 | 11.1 | Sect. | |||||

| S47621 | 24.0 | Sect. B | |||||

| A47921 | 450kN/m | 4.0 | Ears | ||||

| R0.6 | A47061 | 500kN/m | 25.0 | L | |||

| A47561 | 15.3 | M | |||||

| A47762 | 6.0 | SS | |||||

| A47861 | 11.1 | Sect. | |||||

| S47661 | 24.0 | Sect. B | |||||

| A47961 | 450kN/m | 4.0 | Ears | ||||

| R1.5 | R47081 | 500kN/m | 25.0 | L | |||

| R47581 | 15.3 | M | |||||

| R47782 | 6.0 | SS | |||||

| R47881 | 11.1 | Sect. | |||||

| RS7681 | 24.0 | Sect. B | |||||

| R47981 | 450kN/m | 4.0 | Ears | ||||

| R2.3 | R47091 | 500kN/m | 25.0 | L | |||

| R47591 | 15.3 | M | |||||

| R47792 | 6.0 | SS | |||||

| R47891 | 11.1 | Sect. | |||||

| RS7691 | 24.0 | Sect. B | |||||

| R47991 | 450kN/m | 4.0 | Ears | ||||

| R3.0 | A47031 | 500kN/m | 25.0 | L | |||

| A47531 | 15.3 | M | |||||

| A47732 | 6.0 | SS | |||||

| A47831 | 11.1 | Sect. | |||||

| S47631 | 24.0 | Sect. B | |||||

| A47931 | 450kN/m | 4.0 | Ears | ||||

| 88° | R0.2 | B47021 | 500kN/m | 9mm | 25.0 | L | |

| B47521 | 15.3 | M | |||||

| B47722 | 6.0 | SS | |||||

| B47821 | 11.1 | Sect. | |||||

| S4762B | 24.0 | Sect. B | |||||

| B47921 | 450kN/m | 4.0 | Ears | ||||

| R0.6 | B47061 | 500kN/m | 25.0 | L | |||

| B47561 | 15.3 | M | |||||

| B47762 | 6.0 | SS | |||||

| B47861 | 11.1 | Sect. | |||||

| S4766B | 24.0 | Sect. B | |||||

| B47961 | 450kN/m | 4.0 | Ears | ||||

| 88° | R3.0 | R4703B | 500kN/m | 9mm | 25.0 | L | |

| R4753B | 15.3 | M | |||||

| R4773B | 6.0 | SS | |||||

| R4783B | 11.1 | Sect. | |||||

| RS763B | 24.0 | Sect. B | |||||

| R4793B | 450kN/m | 4.0 | Ears | ||||

| 90° | R0.2 | A48021 | 500kN/m | 9mm | 25.0 | L | |

| A48521 | 15.3 | M | |||||

| A48722 | 6.0 | SS | |||||

| A48821 | 11.1 | Sect. | |||||

| A48921 | 450kN/m | 4.0 | Ears | ||||

Gooseneck Type-T No Interference Hardness HRC47±2 * Burring Back Relief Spec. |

86° | R0.2 | T47021 | 500kN/m | - | 24.7 | L |

| T47521 | 15.1 | M | |||||

| T47722 | 5.9 | SS | |||||

| T47821 | 11.0 | Sect. | |||||

| TS7621 | 23.7 | Sect. B | |||||

| T47921 | 450kN/m | 4.0 | Ears | ||||

| R0.6 | T47061 | 500kN/m | 24.7 | L | |||

| T47561 | 15.1 | M | |||||

| T47761 | 5.9 | SS | |||||

| T47861 | 11.0 | Sect. | |||||

| TS7661 | 23.7 | Sect. B | |||||

| T47961 | 450kN/m | 4.0 | Ears | ||||

| 88° | R0.2 | T4702B | 500kN/m | - | 24.7 | L | |

| T4752B | 15.1 | M | |||||

| T4772B | 5.9 | SS | |||||

| T4782B | 11.0 | Sect. | |||||

| TS762B | 23.7 | Sect. B | |||||

| T4792B | 450kN/m | 4.0 | Ears | ||||

| R0.6 | T4706B | 500kN/m | 24.7 | L | |||

| T4756B | 15.1 | M | |||||

| T4776B | 5.9 | SS | |||||

| T4786B | 11.0 | Sect. | |||||

| TS766B | 23.7 | Sect. B | |||||

| T4796B | 450kN/m | 4.0 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Spec. | Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight (kg) |

Size |

| AFH120 Gooseneck Thin Type 6mm (SK11) Hardness HRC47±2 |

|

86° | R0.2 | A46021 | 350kN/m | 6mm | 23.3 | L |

| A46521 | 14.3 | M | ||||||

| A46722 | 5.6 | SS | ||||||

| A46821 | 10.3 | Sect. | ||||||

| S46621 | 22.4 | Sect. B | ||||||

| A46921 | 350kN/m | 3.7 | Ears | |||||

| R0.6 | A46061 | 350kN/m | 23.3 | L | ||||

| A46561 | 14.3 | M | ||||||

| A46762 | 5.6 | SS | ||||||

| A46861 | 10.3 | Sect. | ||||||

| S46661 | 22.4 | Sect. B | ||||||

| A46961 | 350kN/m | 3.7 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Spec. | Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight (kg) |

Size |

| AFH120 Hemming Hardness HRC47±2 |

|

30° | R0.6 | A30061 | 1000kN/m | ---- | 14.7 | L |

| A30561 | 9.0 | M | ||||||

| A30762 | 3.5 | SS | ||||||

| A30861 | 6.5 | Sect. | ||||||

| S30661 | 14.1 | Sect. B | ||||||

| A30961 | 300kN/m | 2.8 | Ears |

- AFH die has special relief in order to gain the perfect alignment and tooling origin. Please be sure to use the same angle for combination to obtain the origin position. If the origin position is determined by different angle combination, the first bend for the product may be more acute than expected angle.

| Profile | Angle | Radius | CATNo. | Allowable Tonnage | Edge Width | Weight (kg) |

Size |

Standard Hardness HRC47±2 |

86° | R0.2 | A94521 | 1000kN/m | 9mm | 8.1 | M |

| A94722 | 3.2 | SS | |||||

| A94821 | 5.9 | Sect. | |||||

| A94921 | 450kN/m | 2.2 | Ears | ||||

| R0.6 | A94561 | 1000kN/m | 8.1 | M | |||

| A94762 | 3.2 | SS | |||||

| A94861 | 5.9 | Sect. | |||||

| A94961 | 450kN/m | 2.2 | Ears | ||||

| 90° | R0.2 | A96521 | 1000kN/m | 9mm | 8.1 | M | |

| A96722 | 3.2 | SS | |||||

| A96821 | 5.9 | Sect. | |||||

| A96921 | 450kN/m | 2.2 | Ears | ||||

Sash Hardness HRC47±2 |

86° | R0.2 | A92521 | 300kN/m | 8mm | 5.5 | M |

| A92722 | 2.1 | SS | |||||

| A92821 | 4.0 | Sect. | |||||

| A92921 | 150kN/m | 1.7 | Ears | ||||

| R0.6 | A92561 | 300kN/m | 5.5 | M | |||

| A92762 | 2.1 | SS | |||||

| A92861 | 4.0 | Sect. | |||||

| A92961 | 150kN/m | 1.7 | Ears | ||||

| 90° | R0.2 | A91521 | 300kN/m | 8mm | 5.5 | M | |

| A91722 | 2.1 | SS | |||||

| A91821 | 4.0 | Sect. | |||||

| A91921 | 150kN/m | 1.7 | Ears | ||||

Gooseneck Hardness HRC47±2 |

86° | R0.2 | A93521 | 550kN/m | 6mm | 10.0 | M |

| A93722 | 3.9 | SS | |||||

| A93821 | 7.3 | Sect. | |||||

| A93921 | 300kN/m | 2.8 | Ears | ||||

| R0.6 | A93561 | 550kN/m | 10.0 | M | |||

| A93762 | 3.9 | SS | |||||

| A93861 | 7.3 | Sect. | |||||

| A93961 | 300kN/m | 2.8 | Ears | ||||

| 90° | R0.2 | A95521 | 550kN/m | 6mm | 10.0 | M | |

| A95722 | 3.9 | SS | |||||

| A95821 | 7.3 | Sect. | |||||

| A95921 | 300kN/m | 2.8 | Ears | ||||

Straight Hardness HRC47±2 |

86° | R0.2 | A99521 | 500kN/m | - | 4.6 | M |

| A99722 | 1.8 | SS | |||||

| A99821 | 3.3 | Sect. | |||||

| A99921 | 120kN/m | 1.4 | Ears | ||||

| R0.6 | A99561 | 500kN/m | 4.6 | M | |||

| A99762 | 1.8 | SS | |||||

| A99861 | 3.3 | Sect. | |||||

| A99961 | 120kN/m | 1.4 | Ears | ||||

| 90° | R0.2 | A98521 | 500kN/m | - | 4.6 | M | |

| A98722 | 1.8 | SS | |||||

| A98821 | 3.3 | Sect. | |||||

| A98921 | 120kN/m | 1.4 | Ears | ||||

Acute Hardness HRC47±2 |

30° | R0.2 | A90521 | 500kN/m | - | 4.5 | M |

| A90722 | 1.8 | SS | |||||

| A90821 | 3.3 | Sect. | |||||

| A90921 | 120kN/m | 1.3 | Ears | ||||

| R0.6 | A90561 | 500kN/m | 4.5 | M | |||

| A90762 | 1.8 | SS | |||||

| A90861 | 3.3 | Sect. | |||||

| A90961 | 120kN/m | 1.3 | Ears |