- Special Tools Guide

- Curling Double-Deck Type

Curling Double-Deck Type

SPCC : 0.6 - 2.3mm SUS : 0.6 - 1.5mm

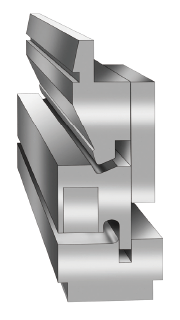

The two operations of U-bend and curling are made using one tool. No tool change is required and set-up time is reduced for mass-production. (Height-adjustment is required for each process.)

| Work Sample | Work Profile | Tool Image |

|---|---|---|

|

|

|

Tool Spec.

| Mat. | SPCC, SUS, AL |

| Thickness mm | 0.6 - 2.3(SUS less than 1.5) |

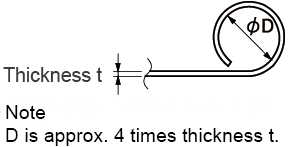

| Inner Radius (D) mm | t x 4 - 1.5 |

Required Tonnage

Required bending tonnage /per m(SPCC) unit kN/m| Thickness mm | 0.6 | 0.8 | 1 | 1.2 | 1.6 | 2 | 2.3 |

|---|---|---|---|---|---|---|---|

| Required Ton kN/m | 200 | 260 | 330 | 400 | 530 | 660 | 760 |

* Required Tonnage kN/m=330×Thickness * Multiply x 1.5 to above figure for stainless steel, and x 0.6 to Al A5052.

Necessary Tonnage Calculation

| SPCC | Tonnage /m above x1.0 x product length(mm)÷1000 |

|---|---|

| SUS | Tonnage /m above x1.5 x product length(mm)÷1000 |

| AL | Tonnage /m above x0.6 x product length(mm)÷1000 |

Cautions

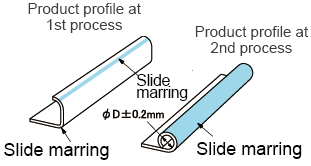

Marring

Both processes of 1st and 2nd have marring as shown below.

Check Machine Capacity

Be sure that required tonnage gained by equation above does not exceed the machine capacity.

Product Accuracy

Product inner diameter accuracy φD ±0.2mm.

Open Hight

Distance piece has to be removed when this type tool is used on open-height 300mm.