- Special Tools Guide

- Trapezoidal hat-Bending (Counter-Type)

Trapezoidal Hat Bending (Counter-Type)

SPCC : 0.6 - 2.0mm SUS : 0.6 - 1.2mm

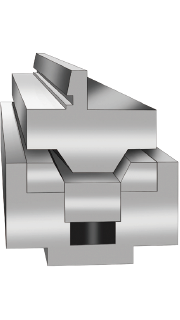

This tool creates trapezoid-shape (like Hat shape ) groove by one operation. Four (4) bends can be made all in one operation material and no turning is required. Product flatness and dimensional accuracy is well satisfied.

| Work Sample | Work Profile | Tool Image |

|---|---|---|

|

|

|

Tool Spec.

| Mat. | SPCC, SUS, AL |

| Thickness mm | 0.6 - 2.0(SUS less than 1.2) |

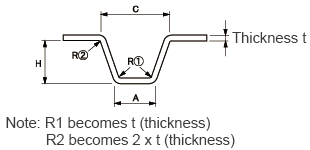

| Hight (H) mm | (t x 5) - 15 |

| Width (A) mm | (t x 4) - 30 |

Required Tonnage

Required bending tonnage /per m(SPCC) unit kN/m| Radius mm | 5 | 10 | 15 | 20 | 30 | |

|---|---|---|---|---|---|---|

| Thickness mm | 0.6 | 260 | 250 | 250 | 240 | 240 |

| 0.8 | 360 | 340 | 340 | 340 | 330 | |

| 1 | 460 | 430 | 420 | 420 | 410 | |

| 1.2 | - | 510 | 500 | 500 | 490 | |

| 1.6 | - | 700 | 680 | 670 | 660 | |

| 2 | - | 890 | 870 | 850 | 840 | |

* Multiply x 1.5 to above figure for stainless steel, and x 0.6 to Al A5052

Necessary Tonnage Calculation

| SPCC | Tonnage /m above x1.0 x product length(mm)÷1000 |

|---|---|

| SUS | Tonnage /m above x1.5 x product length(mm)÷1000 |

| AL | Tonnage /m above x0.6 x product length(mm)÷1000 |

Cautions

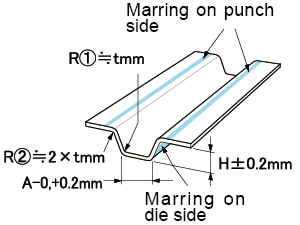

Marring

Marring appears on the punch hold-down area and die side surface.

Check Machine Capacity

Be sure that required tonnage gained by equation above does not exceed the machine capacity.

Product Accuracy

Product height accuracy becomes ± 0.2mm.

Product width A accuracy -0, +0.2mm

R1 radius becomes t (material thickness) and R2 becomes t x 2